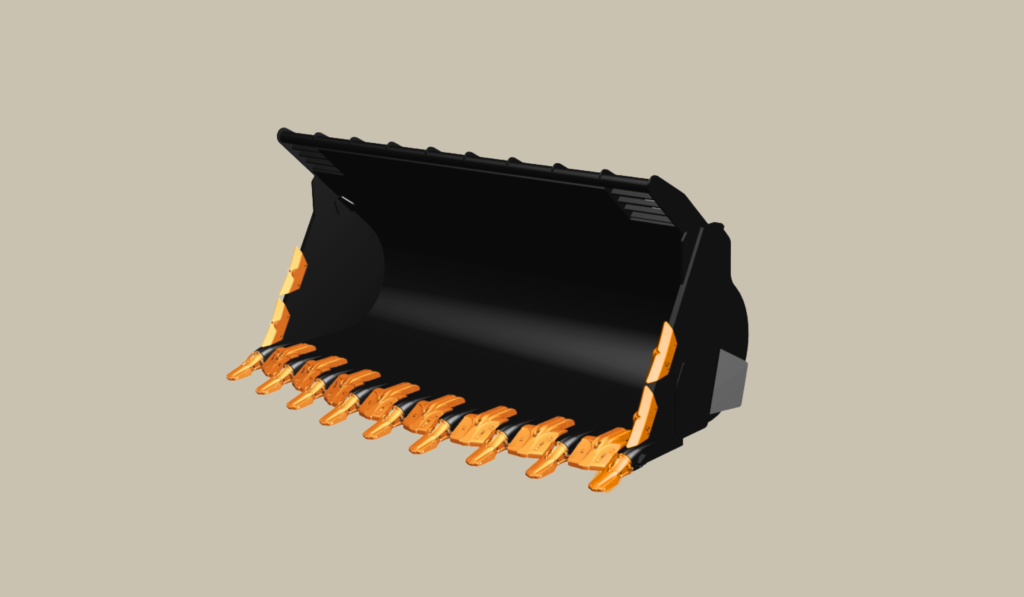

ProClaws wear part solution for wheel loaders

Upgrade your productivity with ProClaws – our cutting-edge wear parts system crafted to deliver unparalleled results. Ensuring consistent and reliable operation across a wide spectrum of equipment sizes, ranging from 10-ton to 250-ton machines, ProClaws stands as the ideal partner.

Experience unmatched performance, efficiency, and reliability with ProClaws.

Fits Every bucket size and machine model

Irrespective of the machine brand or model, ProClaws offers universal compatibility, fitting buckets ranging from 20 mm to 140 mm.

Exceptional tooth strength

With a significant amount of wear material, utilizing up to 74% of the tooth’s original weight, ProClaws maximizes durability and minimizes the need for replacements.

The perfect partner for demanding applications

ProClaws is the perfect partner for diverse applications including coal, copper, frozen ground, clay, stone, abrasive applications, and hard minerals.

Reduce fuel costs and downtime

Maximize the penetrating power of ProClaws on your wheel loader for reduced fuel costs and enhanced productivity. Benefit from swift and effortless tooth replacements, minimizing downtime and extending machine operation. ProClaws’ sturdy holders ensure fewer breakages and reduced maintenance, while its long-lasting teeth save on replacements. With ample wear material on each tooth, ProClaws delivers optimal performance and hassle-free tooth replacements. Achieve exceptional efficiency and durability with ProClaws.

ProClaws signature features

User-friendly locking system

Discover the intuitive lock mechanism of ProClaws, setting new standards in cost-effectiveness and dependability. Our easy-to-use design enables the reuse of locking pins and includes a pre-installed locking ring with every new tooth, guaranteeing safety and optimal functionality. Elevate your wheel loader operations with ProClaws and experience the convenience of the adjustable and tight lock mechanism, ensuring a perfect fit between tooth and holder without any play.

Wear monitoring capability

Stay proactive in maintenance with ProClaws wear monitoring feature, applicable to all sizes. Eliminate guesswork and ensure consistent equipment performance, always maximizing productivity.

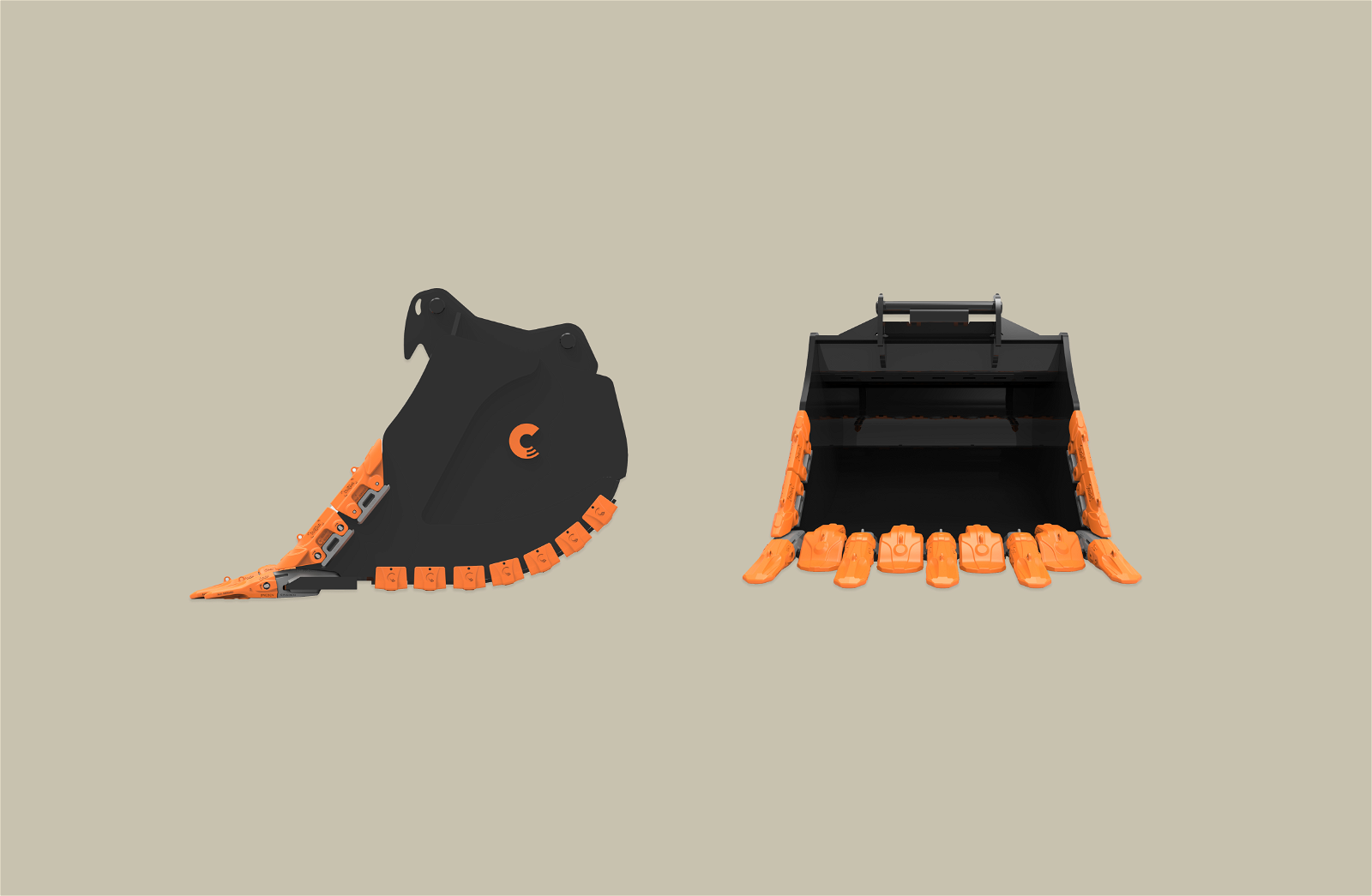

Why you should choose ProClaws for your Wheel loader

Rapid and secure tooth replacements

C-REX offers fast, hammerless tooth changes for rapid and secure replacements.

Sleek profile

C-REX’s slimmed-down profile allows for easy material movement in and out of the bucket, reducing stress on your excavator.

Compatibility for all bucket sizes and machine models

No matter the machine or brand, C-REX offers universal compatibility, allowing you to install it on any bucket with cutting-edge thickness ranging from 20 – 140 mm.

Tooth durability

With a remarkably high percentage of wear material, up to 74% utilization of the tooth’s original weight, C-REX maximizes longevity and minimizes downtime and the need for replacements.

Made in Sweden with short lead times and Swedish steel

Choose C-REX and support ethical practices. Our wear parts are proudly made in Sweden, prioritizing clean energy, worker safety, and rights – all crafted from high-quality Swedish steel. Additionally, we ensure excellent availability and prompt delivery to keep your operations running smoothly.

Protect your bucket with our ProTect range

Our ProTect range is specifically designed to safeguard your bucket. With lip shrouds, side shrouds, wear caps, heel shrouds, and ProMite wear protection, you can ensure optimal protection and an extended lifespan.

Our mechanical lip- and side-shrouds protects the front of the bucket, while heel shrouds protects the outside bottom corners. The ProMite wear protection, available in different shapes and sizes to fit exposed areas are made out of white iron with a hardness of 700 HB.

Explore our range and preserve the performance and durability of your equipment.

A long lasting partnership

The design of the C-REX makes it suitable for many different areas of work. It will always deliver, no matter what. If you have any further questions you are always welcome to contact us.